Solar panels have become more affordable than ever due to manufacturing efficiencies. They are increasingly seen on rooftops of many homes and commercial properties.

But what solar panels are made of and how solar panels are manufactured remains a mystery to many people who value installing solar panels on their home, business, farmland or property.

If you want to know more about how a solar panel is made, read on for more information.

What are solar panels made of?

Most solar panels are made of silicon wafers. Silicon is abundant on our planet. In fact, it is the second most available element on earth, second only to oxygen. And it is with this chemical element, silicon, that the whole process of manufacturing photovoltaic cells and solar panels begins.

Having silicon as the basis for the manufacture of a solar panel and its base plate where the cells are glued, we find other parts when forming a solar panel, such as the glass cover, steel frame that ensures the integrity of the panel and joins all parts, terminal box and protection diodes, which ensure the flow of electric current.

Gallium arsenide is also used, although these are manufactured mainly for photovoltaic use.

Silicon in solar panels

Solar cells are made from crystalline silicon that is melted and then mixed with gallium or boron to form wafers called silicon ingots. Phosphorus is then added to the silicon and, together with gallium or boron, gives the silicon its electrical capacity.

These silicon wafers are cut as thinly as possible into thin sheets to reduce waste and increase production efficiency.

Because pure silicon is shiny, it reflects sunlight.

To reduce the amount of sunlight lost, an anti-reflective coating is placed on the silicon wafer.

Monocrystalline solar panels are formed from one silicon fragment, but for polycrystalline panels, many silicon fragments are fused into a large sheet to form the silicon wafers of the solar panel.

How are solar panels made?

So, we already know that silicon is an essential component in how a solar panel is made, but what is its manufacturing process?

Silicon is heated at high temperatures in a furnace. Once melted, we obtain ingots in the shape of a cylinder.

When the ingots have cooled completely, they are polished to produce smooth, flat sides. Once the ingot is smooth and even, disks, also known as silicon wafers, which are only a few millimeters thick, are cut. The silicon wafers are cut as thinly as possible to reduce waste and increase production efficiency.

A metallic conductor such as boron is then added to the silicon wafers to give them their electrical capacity. The solar cells are unbalanced to conduct energy, so when the solar panel is formed, these cells are layered and soldered together in a grid-like array.

Finally, a robust, weather-resistant glass is placed on top. The glass is added during the manufacturing process and the solar panels are coated with an anti-reflective coating that encourages the absorption of sunlight, rather than reflecting it.

How do solar panels work?

When sunlight hits the panel, the imbalance stimulates the electrons in the solar cells to move to correct each other. This process is responsible for generating electricity.

The panels capture the sun’s rays and transform them into electricity by means of the photovoltaic cells that cover them.

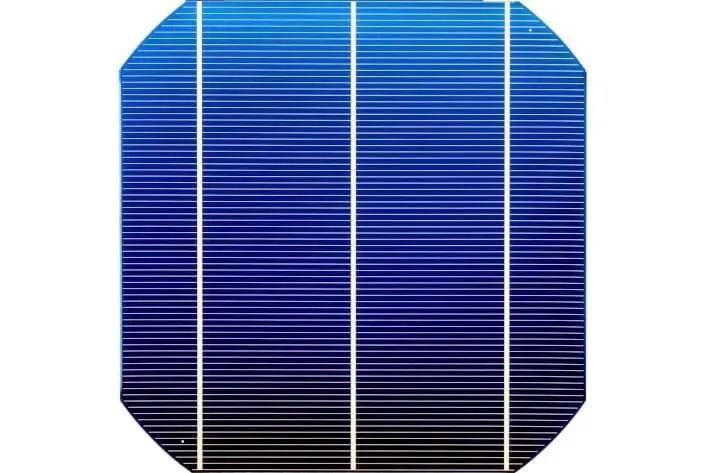

It is worth noting the grooves that make up the solar cells and that are precisely the conductors of electricity.

The solar cells (photovoltaic cells) are electrically connected to each other in series and parallel, thus achieving the necessary voltage for their use.

And this electricity collected from the solar panels is converted from direct current to alternating current through an inverter, which we then consume in our home.

Conclusions

With this article, we have talked about the whole manufacturing process of a solar panel and the most important component, the silicon.

Although if we go into detail, there are other processes included in the manufacture of solar panels such as cleaning the wafers to remove irregularities and surface defects remaining after cutting into wafers or also a test, once the manufacturing process of the cells, where the defective ones are removed according to their characteristics of voltage and current supplied.

We hope you now know a little more about the whole process of how a solar panel is manufactured.

Leave a Reply